CONSULTATION SERVICES AND SELECTION OF RAW MATERIALS

CONSULTATION SERVICES AND SELECTION OF RAW MATERIALS

• Solid technical know-how that puts us in a position to be able to advise clients in finding the most suitable materials for their specific needs (e.g. aluminium alloys, magnesium, titanium).

• Availability of high-end raw materials thanks to our access to a first-class supply chain in the aerospace and automotive sectors.

• Continuous innovation where raw materials and surface treatments are concerned, through collaboration with the most advanced international research centers.

• Solid technical know-how that puts us in a position to be able to advise clients in finding the most suitable materials for their specific needs (e.g. aluminium alloys, magnesium, titanium).

• Availability of high-end raw materials thanks to our access to a first-class supply chain in the aerospace and automotive sectors.

• Continuous innovation where raw materials and surface treatments are concerned, through collaboration with the most advanced international research centers.

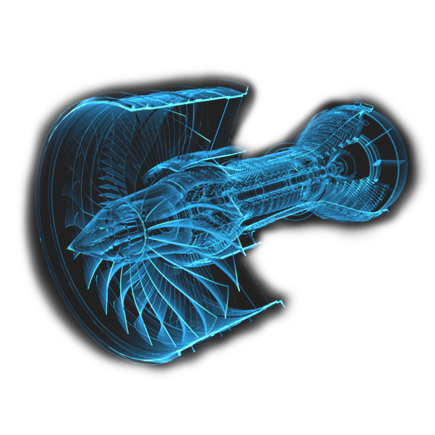

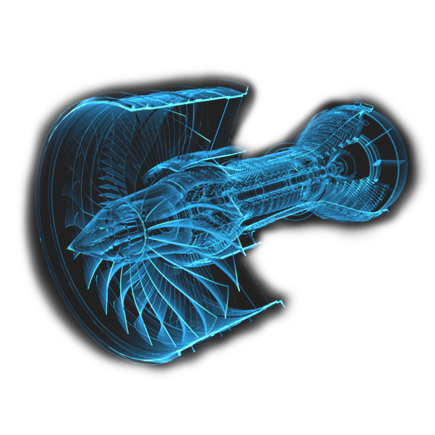

ENGINEERING AND DESIGN SUPPORT

ENGINEERING AND DESIGN SUPPORT

•• We utilize the best software on the market, 3D Experience – Catia’s latest evolution.

• Product development: we elaborate and design concepts according to the customer’s style, thus making for all-around and safe engineering.

• Finite Element Analysis (FEA)

• Product and production process engineering.

• Optical metrology and Reverse Engineering. It is possible to create, with laser scans, prototypes of scale models and other types of finished and semi-finished products.

•• We utilize the best software on the market, 3D Experience – Catia’s latest evolution.

• Product development: we elaborate and design concepts according to the customer’s style, thus making for all-around and safe engineering.

• Finite Element Analysis (FEA)

• Product and production process engineering.

• Optical metrology and Reverse Engineering. It is possible to create, with laser scans, prototypes of scale models and other types of finished and semi-finished products.

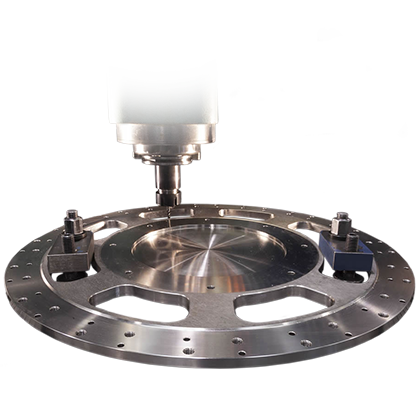

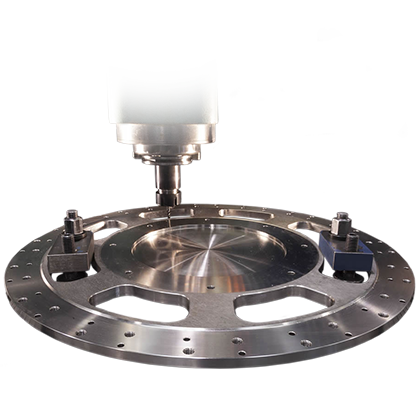

MANUFACTURING OF PARTS ACCORDING TO THE CUSTOMER SPECIFICATIONS

MANUFACTURING OF FORGED PARTS

• Equipment tools for state-of-the-art machining, including 3- and 5-axis CNC work centres.

• Highly-qualified personnel with solid expertise in the production of high-level auto motive and aerospace parts.

• Total process control in compliance with the EN 9100 criteria, ensuring full traceability in each production stage and in product stocking using smart technology.

• Equipment tools for state-of-the-art machining, including 3- and 5-axis CNC work centres.

• Highly-qualified personnel with solid expertise in the production of high-level auto motive and aerospace parts.

• Total process control in compliance with the EN 9100 criteria, ensuring full traceability in each production stage and in product stocking using smart technology.

SUPPLY OF ALUMINIUM AND MAGNESIUM FORGED WHEELS

SUPPLY OF FINISHED AND SEMI-FINISHED PRODUCTS

• We guarantee flexibility in the delivery of items worked on and up to the degree requested by the client, thus maximizing cost effectiveness.

• Prompt and efficient manufacturing of forged wheels, guaranteeing production-to-market optimization time.

• Top-level logistics and after-sales support so as to ensure delivery on schedule. Support for the entire lifecycle of the product.

• We guarantee flexibility in the delivery of items worked on and up to the degree requested by the client, thus maximizing cost effectiveness.

• Prompt and efficient manufacturing of finished and semi-finished products, guaranteeing production-to-market optimization time.

• Top-level logistics and after-sales support so as to ensure delivery on schedule. Support for the entire lifecycle of the product.